Menu / Hardware

- Mould design & manufacture

- Special equipments

- Training services

Training and advisory

BoCan provides both theoretical and practical training to ensure your factory staff can independently run a reliable container production process. Even prior to the start-up of your BoCan molds, we support your team in understanding best practices in injection molding. Let us share over 30 years of international experience to help you reduce time to market. Below are some key areas where we can support your business.

01. Advisory of practical process training

Scope is to define the methodology for providing technical guidance and training in injection molding processes for plastic packaging.

• Technical guidance in best practices for injection molding of plastic packaging.

• Comprehensive review of critical process parameters and optimization.

• Structured sequence for mold setup and programming.

• Improvement of part quality and extension of mold service life.

• Development and implementation of preventive mold maintenance protocols.

• Execution of technical audits to verify process efficiency and compliance

02. Best and optimal polymer selection

The purpose is to establish the procedure for selecting appropriate polymers for the manufacture of plastic packaging.

• Technical assistance in the selection of suitable plastic materials.

• Evaluation of functional requirements and market specifications.

• Detailed analysis and interpretation of material datasheets and related properties.

• Correlation of material features vs manufacturing parameters and expected performance.

Flexural Modulus / Melt Flow Rate / Izod and Charpy Tests / Yied Point / Density

03. Methodology for proper analysis of containers

Focus establishes the methodology for analyzing plastic packaging components to ensure compliance with dimensional, mechanical, and thermal requirements.

• Provision of technical support and training in container analysis.

• Dimensional verification procedures.

• Execution of static and dynamic tests on containers.

• Assessment of stacking performance, impact resistance, and stress distribution.

• Thermal analysis of components with dimensional correlation.

• Implementation of standardized methods to guarantee the quality of plastic containers.

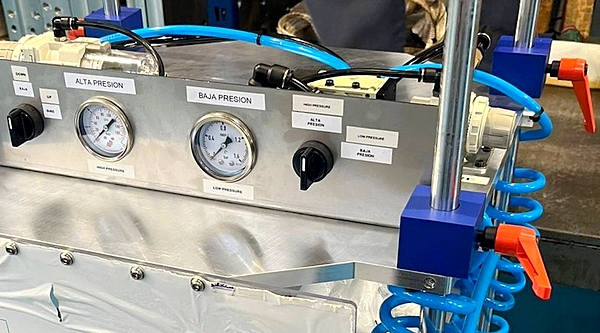

We can also supply basic control equipment, some of which are own made.

04. Support & assistance service

Aim is to support you throughout the entire process to ensure optimal performance and the best end-user experience, from filling lines all the way to the final consumer. Our service is designed to help you get the most out of our packaging solutions at every stage of the supply chain.

• Experience in packaging logistics and distribution, ensuring reliable deliveries tailored to your needs.

• Technical support for filling line issues and adjustments, including troubleshooting, process optimization, and performance improvements.

Our goal is to deliver a responsive, practical, and expert support service, helping your operations run smoothly and efficiently.

Do you have a project to discuss?

Please fill out the form.