Menu / Hardware

- Mould design & manufacture

- Special equipments

- Training services

Mould design & manufacture

Part of our core business is the Design and Manufacture of fast and durable MOULDS for plastic containers. Let us share with you our outstanding expertise when tooling your new moulds. By integrating mold manufacturing with product design, we become your sole partner and attentive collaborator. The integration of the toolshop into BoCan was consolidated starting in 2008 through the synergy of two companies — engineering and workshop — both with a long history in the sector of injection moulding of rigid plastic containers.

Innovative moulds

1. Innovative mould design solutions to minimize the product cost impact.

2. Self-centering packaging molds ensuring uniform wall thickness.

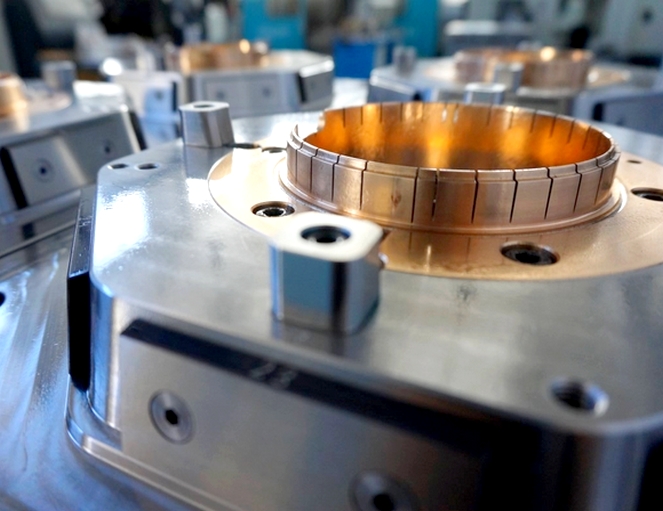

3. High-grade alloys engineered to withstand intensive production.

Best selection of alloys

1. Simple and robust construction to make it durable.

2. Improved cooling design for faster and consistent cycling.

3. Optimal selection of the high-end hotrunner systems.

In-mould-label compatible

1. Moulds are optimized to run with in-mould-label technologies.

2. Reverse gated lid moulds to make them compatible with iml.

3. Smart ejection design -air & mecahical- to ensure fast component removal.

Support and monitoring

1. Comprehensive monitoring of all tooling phases and commission of moulds.

2. Single face moluds, multi-cavity and stack moulds or unbalanced ones.

3. Advising of a wide sort of options, spouts, breathers, materials, gaskets, etc.

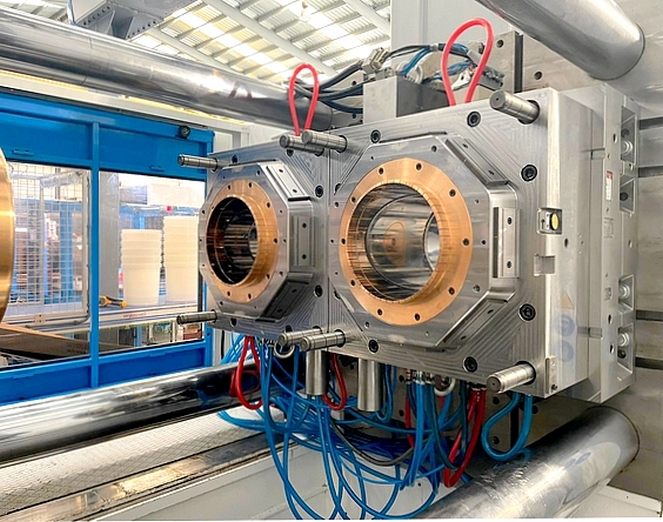

Our toolmaking facilities

Our tool shop is located near to Alicante, Spain. The facilities occupy an area of 800 square meters with a production capability of around 17.500 hours per year. The injection mould test shop is next to our plant and contains machines from 100tn up to 1100tn where small production runs can be ordered as well.

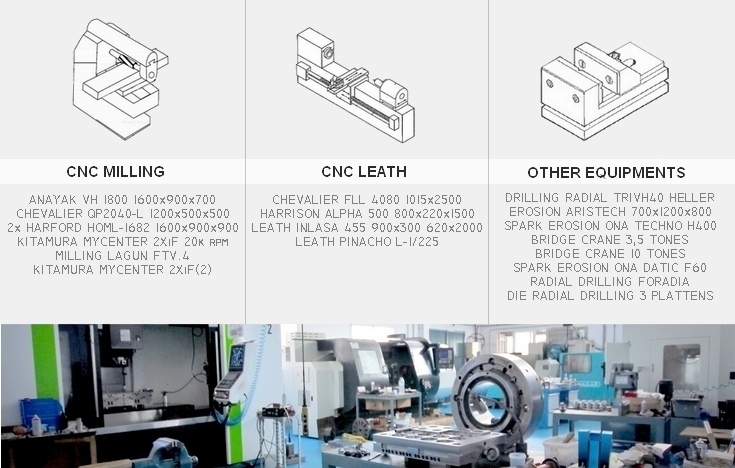

Brief list of our main hardware can be found in the right. Packaging moulds up to 9000Kg (heaviest ever). Design and machining are supported by Missler (CAD), Autodesk (CAD/CAE) and Cimatron (CAD/CAM) licenses.

Tooling facilities

Main area of the tooling premises including the cnc milling machines (rough tooling & fast milling) as well as the leathe for wide parts. Toolshop was completelly restored in 2014 and new machines and devices have been acquired from this date.

Two teams, one vision

When the precision of the design team meets the expertise of the production team, the result is more than just a mould — it’s a custom-built solution. Every part we create is the product of real synergy between technical skill and shared commitment. Engineering & Tooling.

Do you have a project to discuss?

Please fill out the form.