⇒ Performing features of each model in a scale 0-100%. This may guide you selecting the suitable container to match your market needs. Ask for extended info of each characteristic.

Find out more info▼

In this section, you will find a selection of pictures and short descriptions showcasing some of the designs we have created, along with a few examples of moulds and other related information. If you would like to explore any of these projects in greater detail or have specific questions, please don’t hesitate to reach out to us at bocan@bocan.biz

- 01. Yellow SuperPail 23L

- 02. SuperPail 23L flexspout lid

- 03. SuperPail lid mould detail

- 04. UN test / Hydraulic pressure

► Yellow SuperPail UN series container with pourer spout. Homologated according to UN/ADR for flammable liquids Group III. Weight pail=850g / Weight lid=210g / Weight handle=35g / Cycle time pail=20s / Cycle time lid=18s / Resin=HDPE high impact mfi=4.

► Coloured homologated UN lids for a 23L SuperPail. Including ultrasonic welded pourer spout. Weight=210g / Wall thickness=1,9mm / Mould achieves 18s cycle time in a 350tn moulding machine. The UN SuperPail patent was filed in Turkey and Germany and a European Patent was also granted.

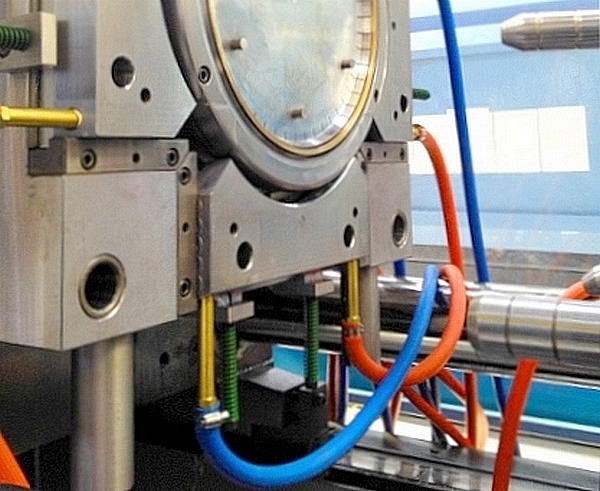

► Single cavity lid mould for a UN series SuperPail lid with peel-off tear band. Cycle time=19s / Wall thickness=1,9mm / Resin HDPE mfi=8. Special 3-step ejection sequence and improved cooling.

► UN tests for flamable liquids requires among other chalenges to submit the container under water pressure for more than 1bar and 30min. No drops to be observed. The one in the picture was tried at 1,6bar for the same time with success.

![]()